The STEVIAL company has a large stock of new or used equipment all rates that can be resold either restored or in the state. A sample of this second-hand equipment is visible on the Agriaffaires website.

Bottling equipment for all types of drinks (fruit juice, mineral water …) available on request.

Find below all our new equipment

Vats

Vats

Pneumatic pump

Pneumatic pump with membrane

Thermotaxis

The thermoregulation allows to control the temperatures of fermentation.

Activator of yeasts : Yeast Booster

Yeast-Booster (activator of yeasts) is a compact and mobile unity for the reactivation, the distribution and the optimal progress of the cells of yeast for the fermentation.

Group of cold : Chilly Max II

Group of cold : MCK I

Temperature control

Filtration

Horizontal screens filter

Sheet filter

Lees filter

Cross-flow filter

The advantages of Romfil Beer Filtration Systems at a glance:

- Automated filtration

- Only one filtration

- High-class organoleptic results

- Outstanding foam stability

- High cost efficiency

- Energy saving

- Residual amount

- Compliant to the German Reinheitsgebot

Depalletization

Centering device of layers for not encircled pallets

Rinçage

Machine allowing the rinsing, the avinage and the sterilization of empty bottles before filling.

Monobloc : Rinsing / Filling / Capping

Example of turret of rinsing gone up in a monoblock.

Rinsing machine

Filling

Fillers for still products like wine, liqueur, water, juice, … and for sparkling products such as Champagne, sparkling wine, beer, water, sodas,…

Rinser, Filler, Corker Fimer

Compact machine for the rinsing, deaeration, filling and closing of glass bottles.

Filler-Screwcapper Fimer

Monoblock equipped with orientation of screw caps 30 x 60 mm.

Advantage:

Big capacity of the hopper and dimensions reduce some removal of capsules.

Gas injection in the bottle and the capsule.

Rinser, Filler, Closer Fimer with angles frame

Compact machine with angled frame and glass protection for rinsing, deaeration, filling and closing of glass bottles.

Advantages : easy cleaning during and at the end of the production.

Electro-pneumatic filling valve.

Filling valve studied to create vacuum into the bottle, to inject neutral gas, to fill the bottle and to make the liquid level into the bottle.

The operations and their duration are programmable thanks to the control panel according to the product and the bottles capacity.

Corking

Crowns capsuling machine

Machine adapted for the distribution and sealing of crown corks.

Multi-head sealing machine

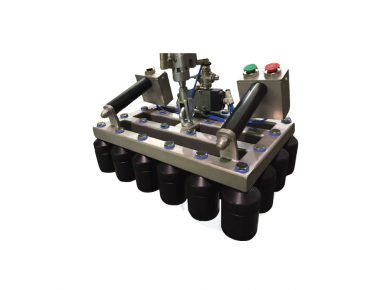

Pneumatic feeder

Adapted for the alimentation of the sealing machine, with screw caps and corkers.

Cork pump

Cork pump designed for the alimentation of the corker (natural or synthetic).

Capacity: from 1.000 to 20.000 corks/hour.

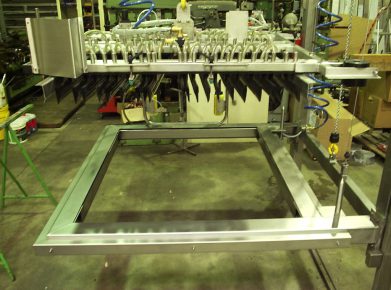

Barrels washer

Barrels washer Stevial

External washer for beer barrels

For 20 to 50-liter beer barrels

Capping machine

Unicap Nortan

Capacity : from 900 to 3000 bottles / hour.

Mechanical engineering, very simple maintenance.

Prisma with heads of shrinkage Nortan

Monoblock adapted to the distribution and to the thermal shrinkage of capsules.

Prisma with champagne heads Nortan

Monoblock adapted to the distribution and and sealing of caps on champagne bottles.

Sleeve Nortan

Labelling machine

Labelling machine BASE

For the labelling and back labelling on cylindrical bottles.

– 1 electropneumatic speed control,

– With the safety protection according to the CE norms.

Capacity : 600-1500 bt/h

380 V – Three-phase.

Labelling machine COMPATTA

For the labelling and back labelling on cylindrical bottles.

– 1 screw of introduction,

– 1 electronic speed variator,

– 1 step by step engine,

– as well as the protection of safety according to standards IT.

Capacity : 2500 bt/h

380 V – Three-phase.

Labelling machine SPEEDY

For the labelling and back labelling on cylindrical bottles.

– 1 screw of introduction,

– 1 electronic speed variator,

– 1 step by step engine,

– As well as of the protection of safety according to standards IT

380 V – Three-phase

Capacity : 3.000 bt / hour max.

Adhesive rotating label machine

This machine allows:

– The pose of several adhesive labels on cylindrical bottles or shape.

Several options are available such as:

– Rotation of stands by step by step engine.

– Orientation with regard to a capsule or a label.

Packing machine

Machine allowing the forming, the packing and the closure of cartons by adhesive tape or hot glue.

Sealing machine

Sealing machine

Allows the simultaneous closure of the superior and lower flaps of cardboards with the adhesive tape. Machine supplied with 1 meter of conveyor with rollers with entrance and a stretchable conveyor going of 1400 to got out of it 4600 mm.

Supplies and consumables

| Small supplies | Consumables |

|---|---|

| – Pipes | – Adhesive tapes |

| – Fittings | – Glue |

| – Foam balls | – Fat |

| – Filter cartridges | – Oil |

| – Valve | – Cork |

| – Air pompe | – Caps |

| – Plastic drums | – Light |

| – Pump rotors | – Cleaning products |

| – Stator | – Filtration consumables |

| – Joints various uses | – Filter plates |

| – Plastic bands and silicones | |

| – Tubing | |

| – Pressure gauges | |

| – Funnels |